A Closer Look at Sustainable Printing

In the previous blog What’s New in Printing Industry,

we’ve discussed some main trends of printing industry nowadays.

Today we’ll dig further into that and find out why digital apparel printing

is more sustainable than traditional one.

In the previous blog What’s New in Printing Industry,

we’ve discussed some main trends of

printing industry nowadays.

Today we’ll dig further into that and find out why digital apparel printing is more sustainable than traditional one.

PASSAGE SUMMARY

1. Why digital printing is more sustainable

Sustainability tend to be divided into three dimensions - environmental, economic and social. To explain why digital printing is much more sustainable than other traditional apparel printing methods, we’ll follow these dimensions but only focus on its positive effects on our environment and society.

1.1 Environmentally friendly

Lower water consumption - take traditional screen printing for instance. Screen printing normally uses stencils and squeegees to produce printings on fabric, and they need to be cleaned by water before and after every printing run.

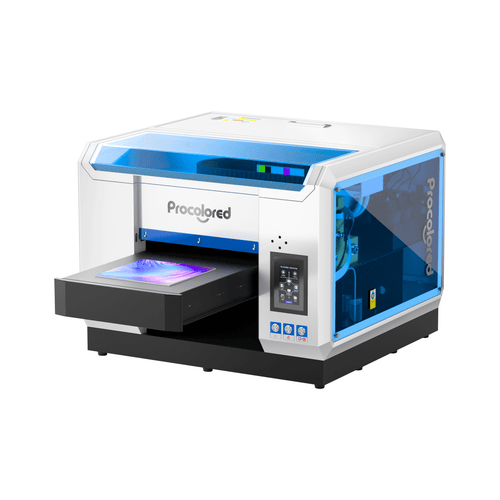

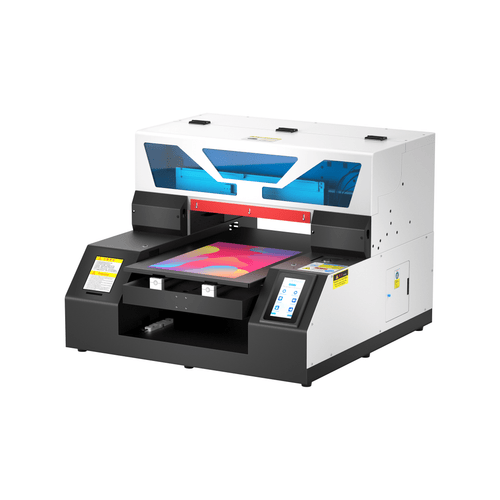

Instead, digital printing relies on printers to do the printing job. Printers will directly print the graphic onto films or fabrics without any rinsing steps needed, thus reducing water consumption.

Lower VOC emission - Volatile organic compounds (VOCs) are organic compounds that have a high vapor pressure at room temperature. Normally it exists in solvents used in traditional apparel printing methods like screen printing or discharge printing. High level of VOC will pollute water and air, worsening climate changing.

Instead, most digital printing methods apply VOC-free inks to finish printing tasks.

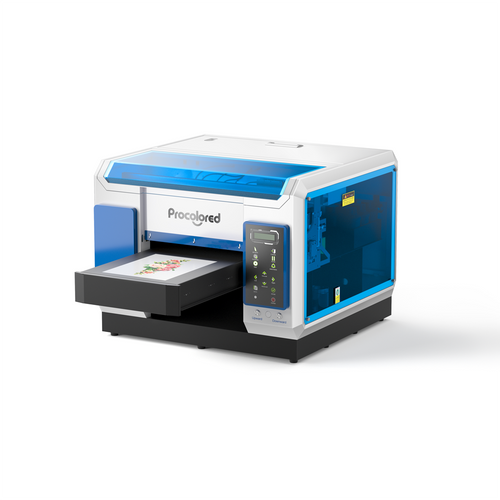

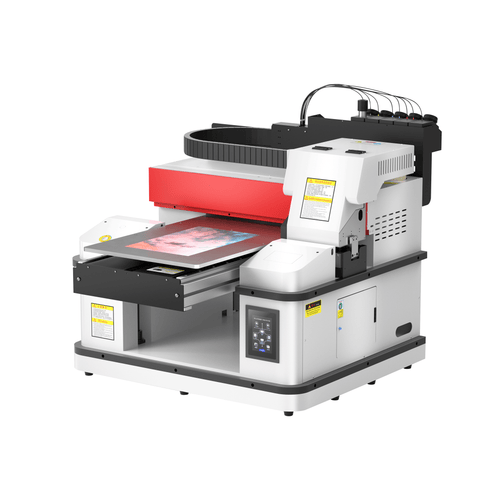

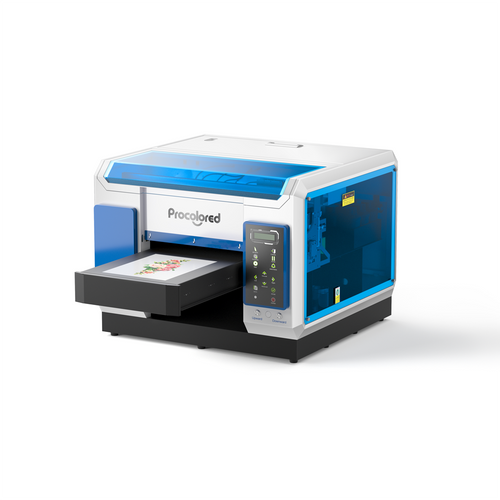

Less waste materials - unlike manual operation of traditional apparel printing, digital printing uses printers to finish the printing job. With gradual improvement of printing technologies, printers nowadays can more accurately translate graphic data from computer and present more precise printings. This improvement not only reduces waste fabric due to wrong or incomplete printings, but also help save inks and electricity.

No excess inventory - in traditional business mode, sellers need to stock numerous apparels on hand to support potential good sales. What makes this mode risky is that once the sales market has been wrongly forecast, sellers will have to handle all the miserable excess inventory by themselves.

Instead, digital printing speeds up the emergence and development of print-on-demand business, which receives orders (of smaller quantities and customized printing patterns) first, then proceed the producing, effectively avoiding excess inventory containing unrecyclable materials.

1.2 Socially sustainable, especially for human health

Reduced exposure to VOCs - as it’s mentioned before, VOCs are organic compounds existing in disposal solvents used in some traditional printing methods. Being exposed to high level of VOCs for a long time will also do harm to human health, causing eye, nose, and throat irritation, headaches or nausea; bringing harm to lung, liver ; and in some extreme cases, leading to cancer.

Unlike most traditional printings, digital printing creates a fresher and cleaner working area with better air condition.

Less physical strain - most traditional printing methods (like block, screen or discharge printing) request manual involvement to press printing onto fabric or clean printing devices, turning every printing task into a labor mission.

Instead, in digital printing process, users are more like executes than workers. They give orders and follow how things are going on, rather than doing repetitive physical works.

Fewer chemical cleanups - we can easily name out lots of chemicals being used in traditional printings, like emulsion in screen printing ; discharge agent, thickener, activators in discharge printing. Digital printing will save you from all those sticky touch and unbearable smell.

2. How do digital printing and sustainability work together

Digital printing has developed rapidly due to its relatively simplicity in operation, equipment and learning curve. It frees users from tedious manual procedures and changes printing tasks into instant artwork creation.

Sustainability has been the main topic of most global issues for years. And even in printing industry, it has been one of the new fashions and prominent selling points.

It seems these two elements emerge and work separately to affect the apparel printing industry nowadays, but in fact they propel and popularize each other during their mutual development.

2.1 Providing continuous propulsion

It’s evident that the progress of printing tools (printer or ink, etc) and printing technologies (inkjet or laser printing, etc) are the dominant momentum of the emergence of digital printing. Yet in the latter part of its development, sustainability trend plays a crucial role in propelling its improvements.

Improvement of ink circulation system - take inkjet printer for example, sediment in ink tank will easily cause ink supply and print head clogging problems, resulting in numerous waste printing sheets and broken printer components. Printers on market nowadays tend to be equipped with developed ink circulation system to reduce ink sediment and improve ink stability.

Improvement of ink formulation - though most digital printing methods apply VOC-free inks, there’s still subtle ink smell spreading during the printing process. To improve this, some ink suppliers start to produce ink with lower-odor formulations or encapsulated solvents which released more slowly over time.

Improvement of product packaging - to thoroughly implement sustainability, more and more printer suppliers develop their product packaging into environmentally friendly materials like boxes of 100% recyclable fibre and at the same time avoid excess packaging by optimizing the box size and design.

Improvement of brand service - besides product research and development, self-owned brands are paying more and more attention to after-sales services and technology support. Detailed operation instructions and instant repairing service in some ways can effectively prolong machine longevity, reducing material waste.

2.2 Extending effective popularization

Sustainability works as one of the biggest selling point of digital printing. That means, whenever the potential users are only browsing or comparing different printing methods, the concept of sustainability, environmental protection or non-manual operation, will be embedded in their minds. And this is the very first step of our magnificent career of sustainability.

A business will thrive only when it’s more easily to be achieved and when it’s lucrative. This is what’s happening to apparel decorating industry - thanks to improvement and popularity of digital printing, more and more business holders are turning from mass manufacturing to easier and lucrative print-on-demand business. And both digital printing per se and print-on-demand business will contribute a lot to sustainability development.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!